鈮鈦合金

Niobium-titanium-alloy.html>titanium alloy is an alloy composed of metal niobium and metal titanium. Here is some information about niobium-titanium alloy:

Characteristics:

Good superconducting properties: When the temperature is below the critical temperature, it exhibits a superconducting function with zero resistance. It is currently a key material in medical nuclear magnetic resonance and superconducting magnets of large scientific devices. For example, in magnetic resonance imaging equipment, particle accelerators and other devices, the superconducting properties of niobium-titanium alloy can generate a strong magnetic field to achieve its specific functions.

Higher melting point: The melting point of niobium-titanium alloy is relatively high, which enables it to maintain good stability in high temperature environments and withstand high temperatures without significant deformation or performance changes.

Excellent mechanical properties: It has the characteristics of high strength, good toughness, and fatigue resistance, and its yield strength is close to that of steel. These mechanical properties enable niobium-titanium alloy to maintain good reliability under large stress or complex stress conditions.

Good corrosion resistance: It has good resistance to a variety of corrosive media, can maintain stable performance in some harsh chemical environments, and is suitable for applications in chemical and other fields.

Preparation method:

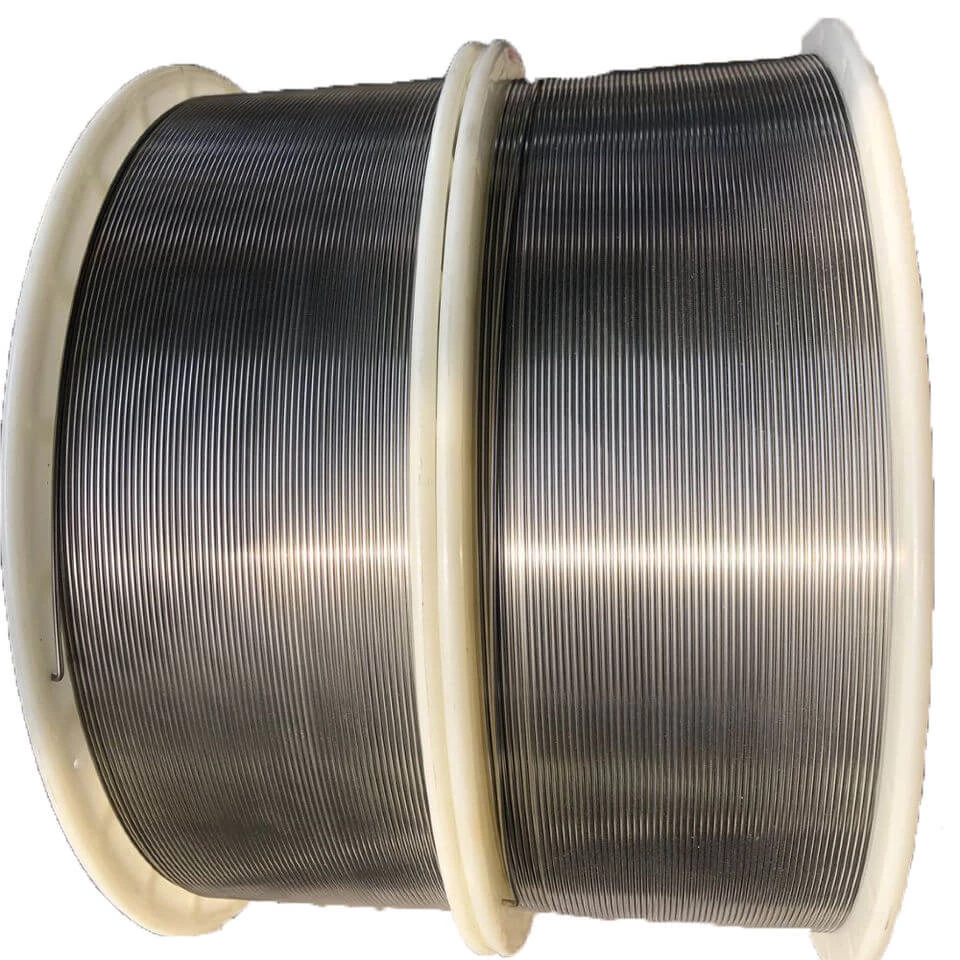

The alloy is sintered with mixed powder and electrodes composed of niobium sheets and titanium sheets, and then melted several times in a vacuum consumable arc furnace or electron beam to form alloy ingots. The alloy ingots are hot extruded or hot forged and then forged and rolled into bars. Then, after subsequent processing, such as cold processing and heat treatment, they are made into products of different specifications and shapes, such as wires and plates.

Application fields:

Niobium-titanium alloys have a wide range of applications, mainly including the following aspects:

Medical field:

Magnetic resonance imaging (MRI): Niobium-titanium alloys are key materials for manufacturing superconducting magnets for MRI equipment. It has the advantages of easy processing, long wire production, relatively low raw material cost, stable and reliable properties, and good superconducting properties. It can generate a strong and stable magnetic field, provide a high-quality imaging environment for MRI, and help doctors accurately diagnose a variety of diseases such as the nervous system, cardiovascular system, digestive system, respiratory system, and urogenital system.

Medical materials: Niobium-titanium alloys have good biocompatibility, high strength, wear resistance, and corrosion resistance, and can be used as new medical materials, such as dental implants.

Large scientific facilities:

Particle accelerators: In particle accelerators, strong magnetic fields are required to control and accelerate particles. The high critical magnetic field and excellent superconducting properties of niobium-titanium alloys make them ideal materials for manufacturing accelerator superconducting magnets. They can provide a stable magnetic field environment for particle acceleration, which is of great significance for basic scientific research and high-energy physics experiments.

Nuclear fusion devices: Nuclear fusion is an important development direction for clean energy in the future. In nuclear fusion devices, strong magnetic fields are required to confine plasma. The superconducting properties of niobium-titanium alloys can meet the requirements of nuclear fusion devices for magnetic fields and provide technical support for the realization of controlled nuclear fusion.

Power field:

Superconducting energy storage: Superconducting energy storage systems can play a role in regulating power quality, balancing power, and improving grid stability in power systems. The superconducting properties of niobium-titanium alloys enable them to efficiently store and release electrical energy in superconducting energy storage devices, thereby improving energy utilization efficiency.

Cables: Although it is still in the research and testing stage, niobium-titanium alloys are expected to be used in the future to manufacture superconducting cables, reduce energy loss during power transmission, and improve power transmission efficiency and capacity.

Aerospace:

Engine parts: Aerospace engines work in harsh environments, requiring materials with high temperature performance, high strength and good oxidation resistance. Niobium-titanium alloys can still maintain good mechanical properties at high temperatures and can be used to manufacture high-temperature engine parts, such as turbine blades, etc., which can reduce engine weight and improve engine thrust-to-weight ratio.

Satellite structural parts: Satellites need to withstand extreme temperature changes and cosmic radiation in space, and have high requirements for material performance. The excellent performance of niobium-titanium alloys enables them to be used to manufacture satellite structural parts to ensure the reliability and stability of satellites.

Chemical industry: Niobium-titanium alloys have good corrosion resistance and can be used to manufacture corrosion-resistant parts in chemical equipment, such as reactors, heat exchangers, pipelines, etc. In chemical production, they can resist the erosion of various chemicals and extend the service life of equipment.

Military industry:

Weapons and equipment: The high strength, high toughness and low density of niobium-titanium alloys enable them to be used to manufacture military products such as armored vehicles, missile shells, and gun barrels, which can improve the performance and protection capabilities of weapons and equipment.

Submarines: Submarines have high requirements for materials and need to have good quiet performance, strength and corrosion resistance. Niobium-titanium alloy can be used to manufacture certain key components of submarines, improving the performance and concealment of submarines.

Excellent superconducting performance:

Moderate transition temperature: Its superconducting transition temperature is 8~10K (Kelvin), which means that below this temperature, the resistance of niobium-titanium alloy will suddenly drop to zero, showing perfect conductivity, and is currently the most widely used low-temperature superconducting material.

Good machinability: Compared with some other superconducting materials, niobium-titanium alloy can be relatively easily processed into various shapes and sizes, such as being drawn into wires and processed into rods, which facilitates its application in the field of superconductivity.

High critical magnetic field: It can withstand higher magnetic fields in the superconducting state, which is very important for manufacturing equipment such as superconducting magnets with strong magnetic fields. For example, in magnetic resonance...

Niobium-titanium alloy has many excellent properties, as follows:

Superconducting performance:

Higher superconducting transition temperature: At a temperature of 8~10K (Kelvin), the resistance of niobium-titanium alloy will suddenly drop to zero, showing superconducting characteristics. This transition temperature is at a relatively high level among many superconducting materials, making it of great application value in the field of low-temperature superconductivity.

High critical magnetic field: It can withstand high magnetic fields in the superconducting state, which is extremely critical for manufacturing equipment such as superconducting magnets with strong magnetic fields. For example, in large scientific devices such as magnetic resonance imaging equipment and particle accelerators, niobium-titanium alloy is an ideal material for manufacturing superconducting magnets.

Good processing performance: Compared with some other superconducting materials, niobium-titanium alloy is relatively easy to process and can be drawn into wires, processed into rods and other shapes and sizes, which facilitates its wide application in the field of superconductivity.

Mechanical properties:

High strength: Niobium-titanium alloy has high strength and can withstand large stresses and loads. This high strength makes it have application potential in fields such as aerospace and nuclear industry that require high material strength.

Good toughness: The alloy has good toughness, can absorb energy when impacted or deformed by external forces, and is not prone to brittle fracture, which is very important for some application scenarios that need to withstand complex stress conditions.

Chemical properties:

Corrosion resistance: Niobium-titanium alloy has good corrosion resistance in a variety of environments and can resist the erosion of chemicals such as acids, alkalis, and salts. This makes it have application advantages in corrosive environments such as chemical and marine environments, and can be used to manufacture corrosion-resistant components in chemical equipment, structural parts in marine engineering, etc.

Physical properties:

Low density: Niobium-titanium alloy has a relatively low density and is a lightweight material. This can reduce the weight of the structure and improve the performance and efficiency of aircraft in some application fields that have strict requirements on weight, such as the aerospace field.

Good thermal conductivity: The alloy has good thermal conductivity and can quickly transfer heat, which is of great significance in some applications that require heat dissipation or heat conduction, such as in the heat dissipation components of electronic equipment.